Class 1 Division 2 Electrical is a type of electrical system that is designed to protect personnel and equipment from the risks associated with combustible dust, water, and volatile gasses. It is a specialized code that is used in hazardous locations where combustible elements are present. The Division 2 code is specifically designed to help lower the risk of accidental ignition of flammable materials by providing a system of electrical components that are designed and tested to meet the highest safety standards.

Class 1 Division 2 electrical systems are used in hazardous locations such as oil refineries, chemical plants, paint shops, and other manufacturing facilities. This type of system is designed to protect personnel and equipment from the risks associated with combustible elements such as dust, water, and volatile gasses. The Division 2 code helps to lower the risk of accidental ignition of flammable materials by providing a system of electrical components that are designed and tested to meet the highest safety standards.

Class 1 Division 2 systems must be designed to protect personnel, equipment, and property from the risks associated with combustible elements. The system must be designed to provide safe operation and to prevent the risk of accidental ignition of combustible materials. The system must also be designed to meet the requirements of the National Electrical Code (NEC).

Class 1 Division 1 v.s. Class 1 Division 2

Class 1 Division 1 and Class 1 Division 2 are two terms used to describe levels of safety regulations in hazardous areas. Class 1 Division 1 is the higher of the two and is typically used in places where combustible gasses, vapors, liquids, dust, fibers, or flyings could be present and might cause an explosion. Class 1 Division 2 is used in areas where combustible gasses, vapors, liquids, dust, fibers, or flyings are not likely to be present in amounts that could cause an explosion.

Class 1 Division 1 areas require that all materials used in the area be rated for use in hazardous locations, as well as all equipment. This includes lighting, wiring, and other electrical components. All materials must be flame-resistant and all equipment must be explosion-proof. This level of safety means that all electrical components must be enclosed in an approved, non-sparking enclosure, and all wiring must be run in conduit.

Class 1 Division 2 areas are a bit less stringent in their safety regulations. Materials and equipment do not have to be rated for hazardous locations, but still must be flame-resistant and explosion-proof. Wiring also does not have to be in conduit, but must be protected from damage.

Explosion Proof Lighting

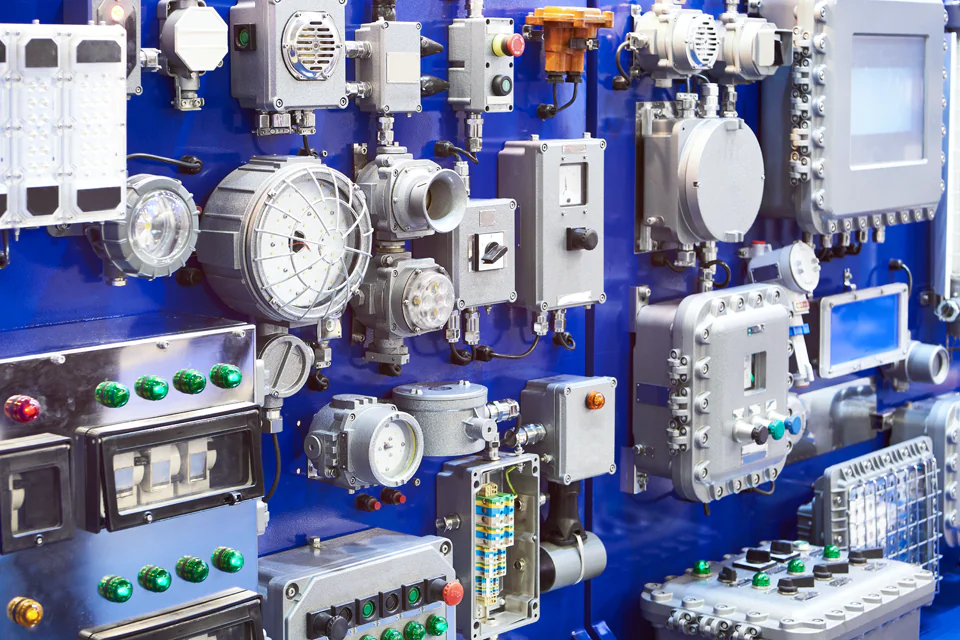

Explosion proof lighting is a specialized type of lighting designed to prevent explosions from occurring in hazardous areas. It is typically used in areas where flammable gasses and combustible dusts are present, such as oil and gas refineries, chemical plants, and mining operations. Explosion proof lighting is designed to contain any spark or flame that could result from an electrical failure or other type of incident.

This type of lighting is constructed with special materials, such as copper and brass, that are able to contain the sparks and flames that could cause an explosion. The individual parts of the lighting are also designed to be airtight and free of any openings that could allow an explosion to occur. In addition, the fixtures are often designed with covers or shields to further reduce the risk of an explosion.

Explosion proof lighting is a critical component of safety protocols in many different industries, and it is vital to ensure that these fixtures are installed properly and maintained regularly.